Bending and cutting of sheet metal

Laser cutting, sheet metal cutting and bending, welding

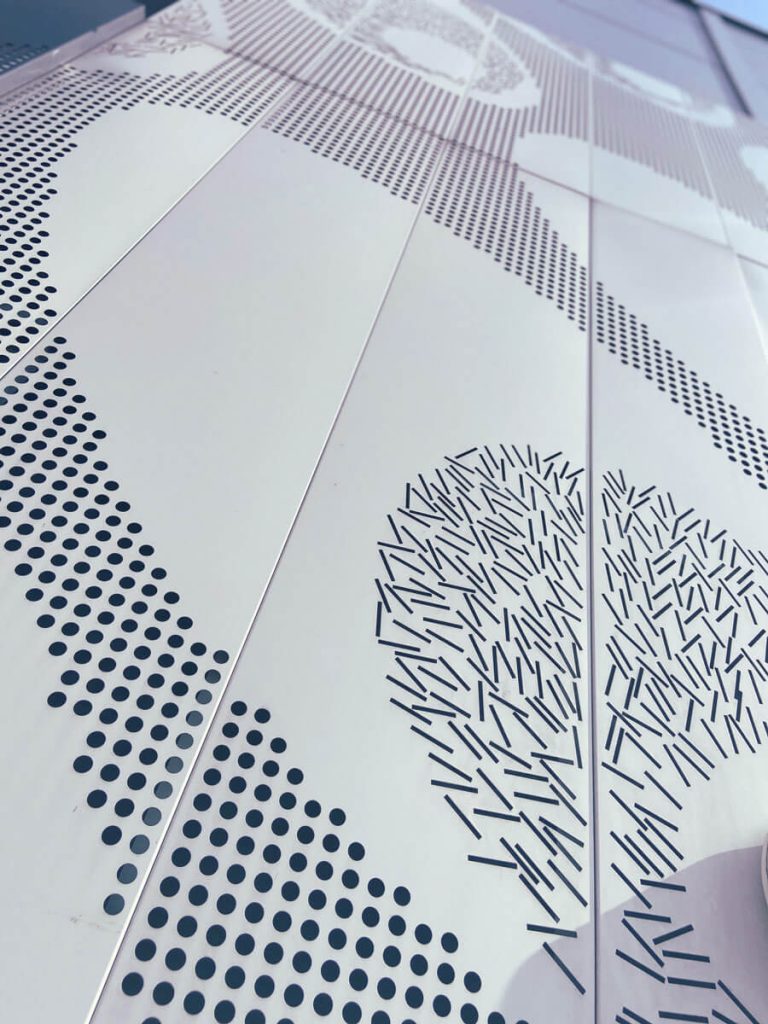

ME Poland’s business is based on specialized knowledge of metals, experience in metal processing, and a unique sense of aesthetics. As one of the few companies in Poland, they can boast of participating in significant and large architectural projects. Their common feature is the highest quality of the used materials and original execution. All sheet metal processing in their version is a work of art! That’s why, when there is a demand for bending and laser cutting of sheet metal, it’s worth relying on professionals, and you can find such experts at ME Poland.

Implemented Projects

For 25 years, this Krakow-based metalworking shop has been offering a wide range of sheet metal processing services. They provide services such as sheet metal cutting, perforation, and even aluminum welding. They work with steel, galvanized, stainless steel, aluminum, and Corten sheets. All tasks, including bending and laser cutting of metal sheets, are always carried out with the highest standards and in accordance with technical norms. Thanks to this, all sheet metal processing does not adversely affect the structure and properties of the metal components. Constantly maintained inventory levels enable fast execution of even custom orders.

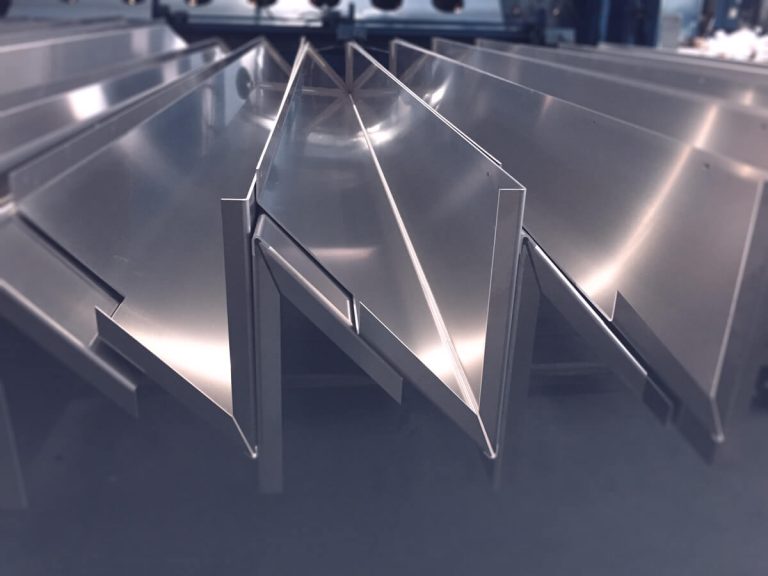

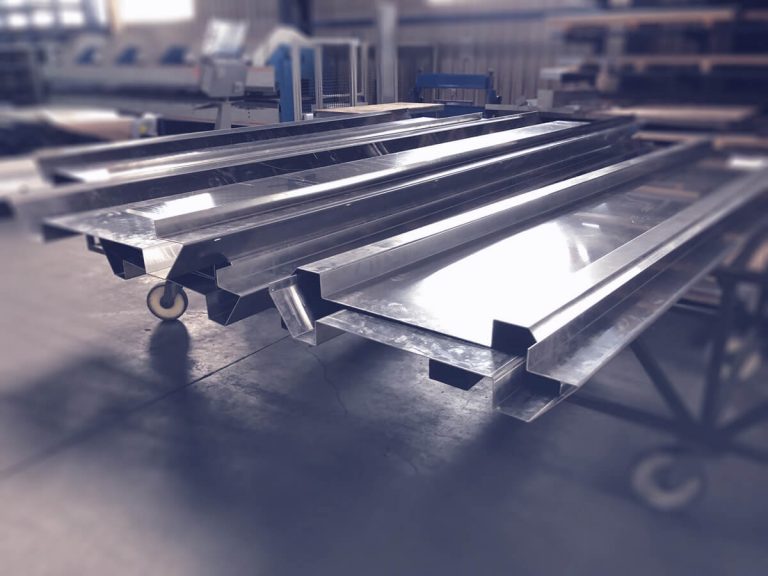

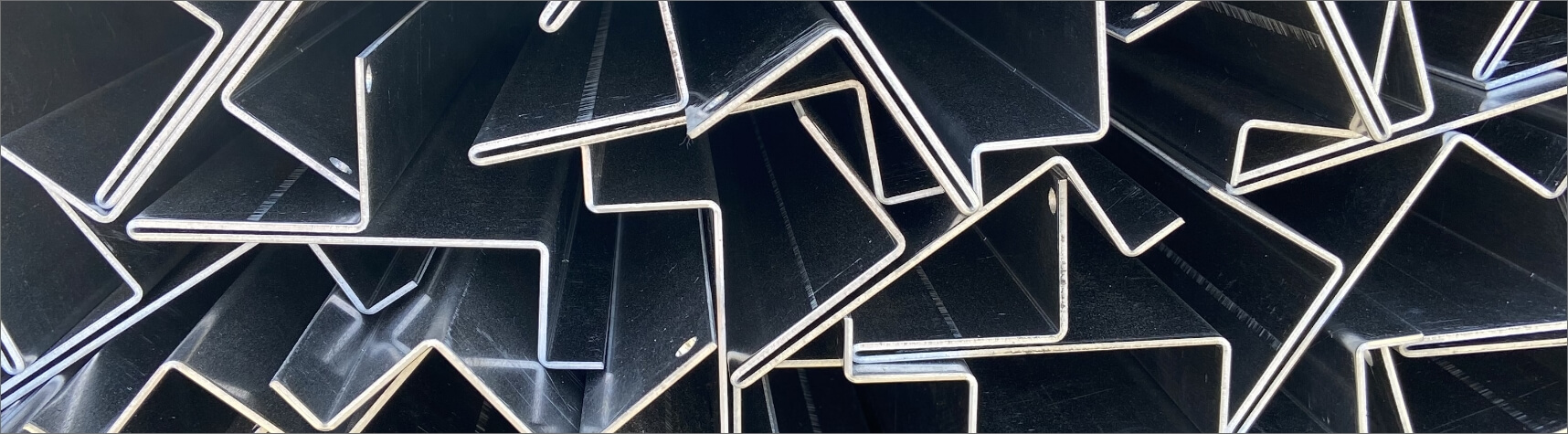

ME Poland provides sheet metal cutting using guillotine shears and cold bending of metal sheets. The company has a machinery park where they utilize numerically controlled CNC press brakes and double-beam folding machines, allowing for bending of elements with complex cross-sections.

Bending and Cutting of Sheet Metal

ME Poland provides sheet metal cutting using guillotine shears and cold bending of metal sheets. The company has a machinery park where they utilize numerically controlled CNC press brakes and double-beam folding machines, allowing for bending of elements with complex cross sections.

Precision bending of sheet metal is essential

As a professional company with many years of experience in the industry, ME Poland emphasizes exceptional precision in executing orders. Even small errors can lead to assembly issues later on. To prevent this, they employ modern production solutions. ME Poland’s machinery park allows for bending of various types of thick steel sheets, including coated ones. Both sheet metal bending and laser cutting are possible for a wide range of dimensions. The machines are adapted for sheet metal processing up to 6200 mm in length and within a thickness range of 0.5 mm to 25 mm.

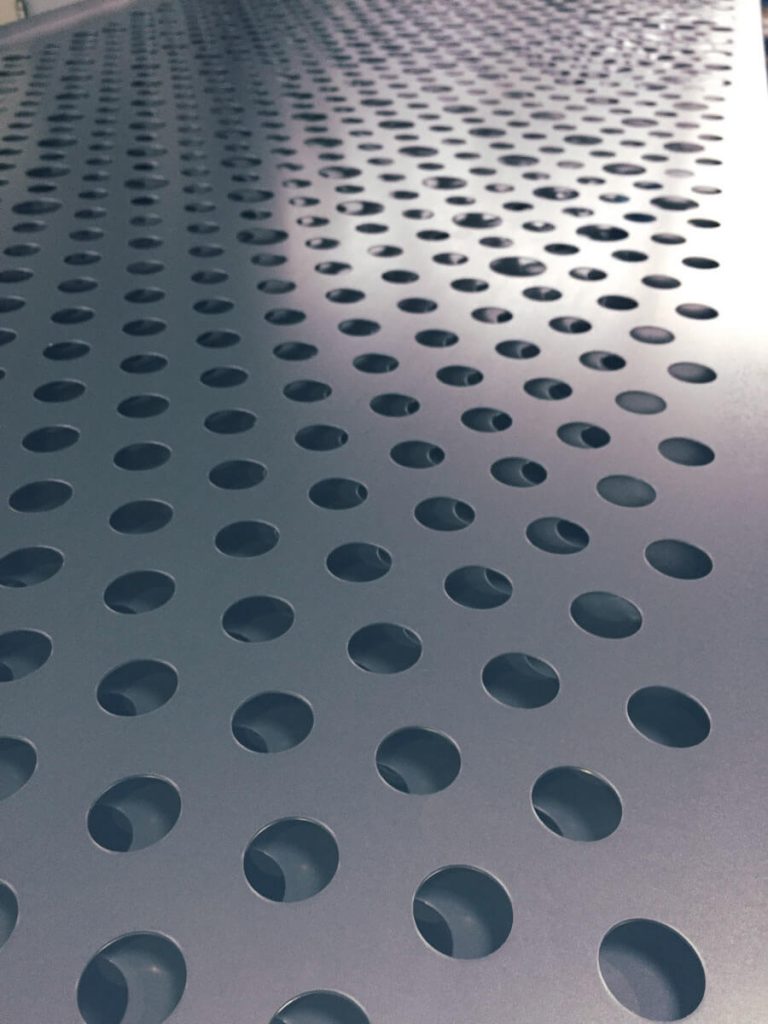

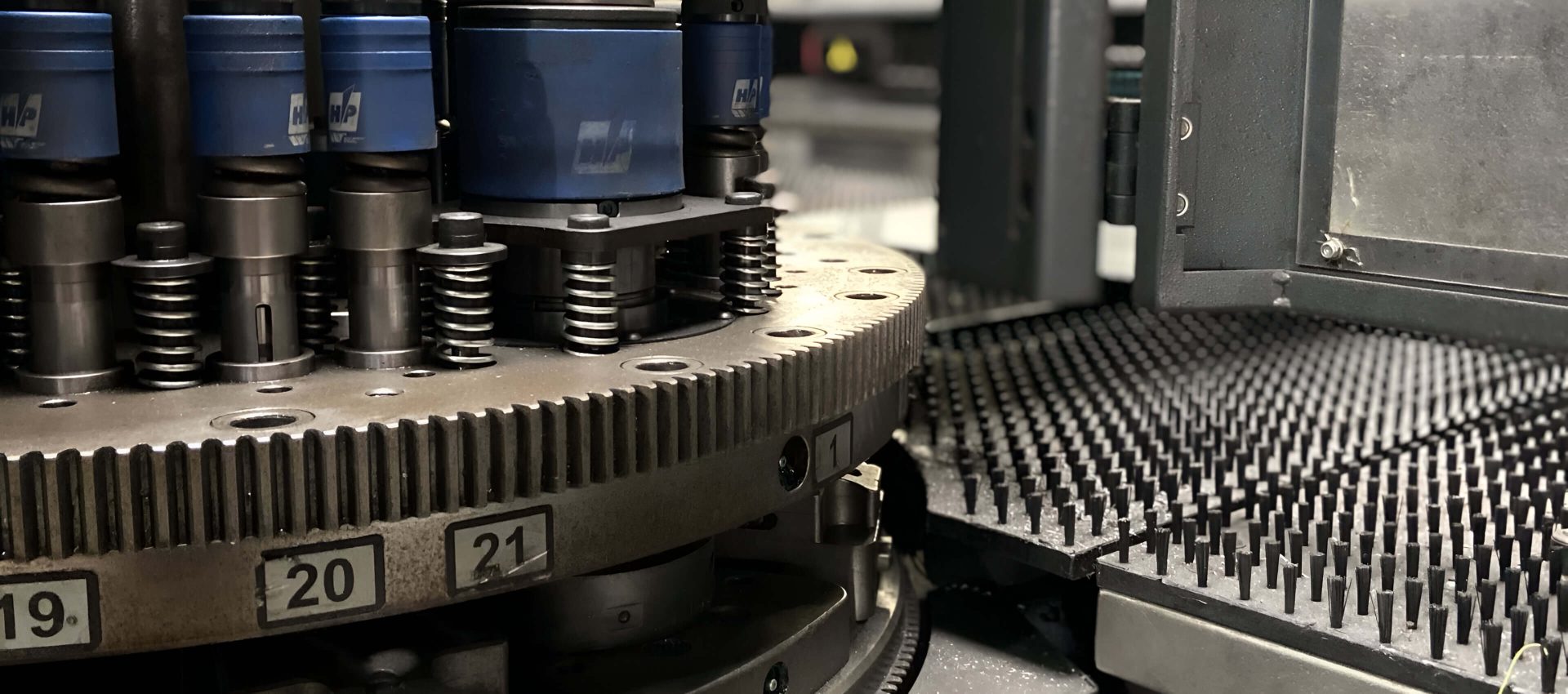

Professional equipment for cutting

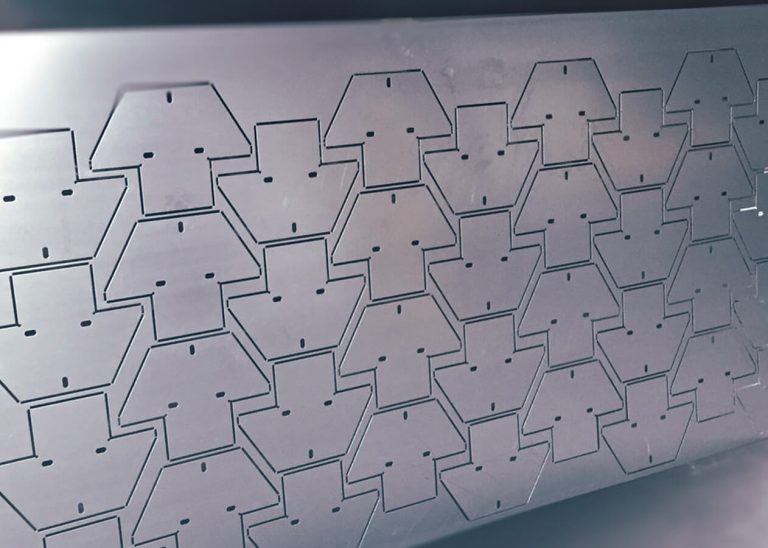

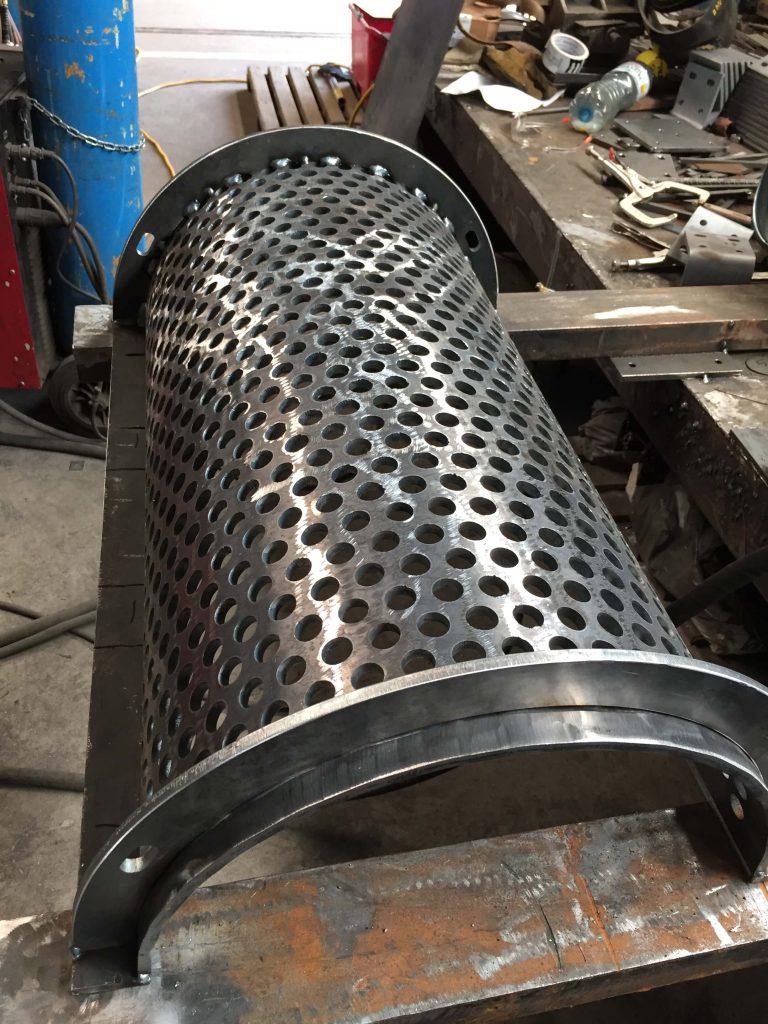

ME Poland utilizes its machinery park to perform custom perforations, blanking, and stamping. As a result, they achieve professionally processed perforated sheets. Perforating sheet metal involves creating various holes in the material. These holes can have different sizes and shapes and can be arranged either regularly or irregularly.

Laser cutting of sheet metal precision and aesthetics.

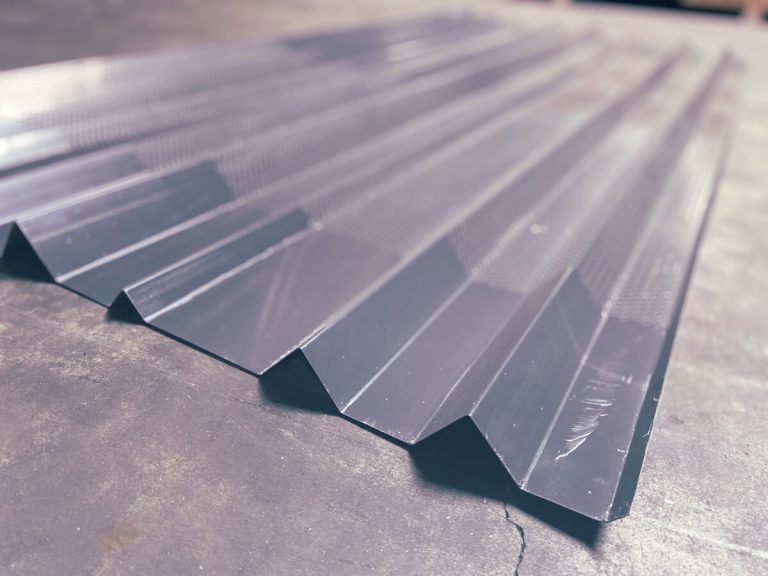

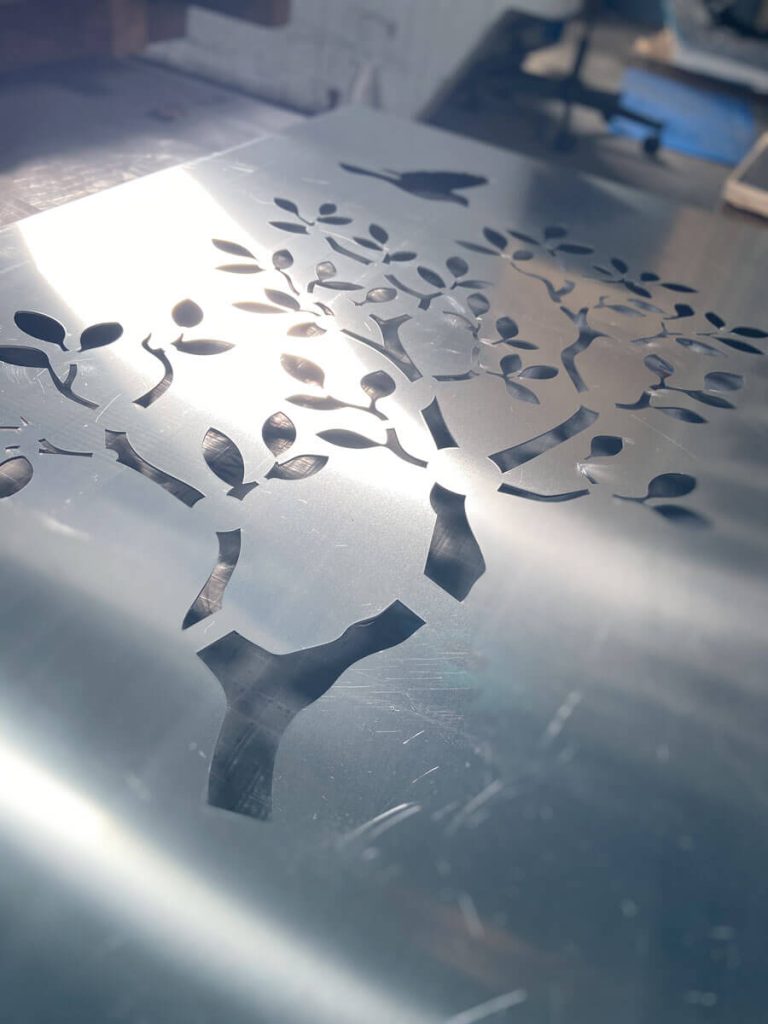

Every professional carrying out various sheet metal processing tasks knows the importance of precise material processing according to the provided dimensions. ME Poland prioritizes customer satisfaction by relying on reliable technologies. By utilizing modern equipment, they can ensure high-precision laser cutting of sheet metal. This is achieved without uneven edges or altering the physical properties of the metal. Laser cutters allow for the cutting of even the smallest details in the material and have a working area of 2000 mm x 6000 mm. After laser cutting, other metal processing processes can be applied, such as bending, stamping, or welding.

Laser Cutting

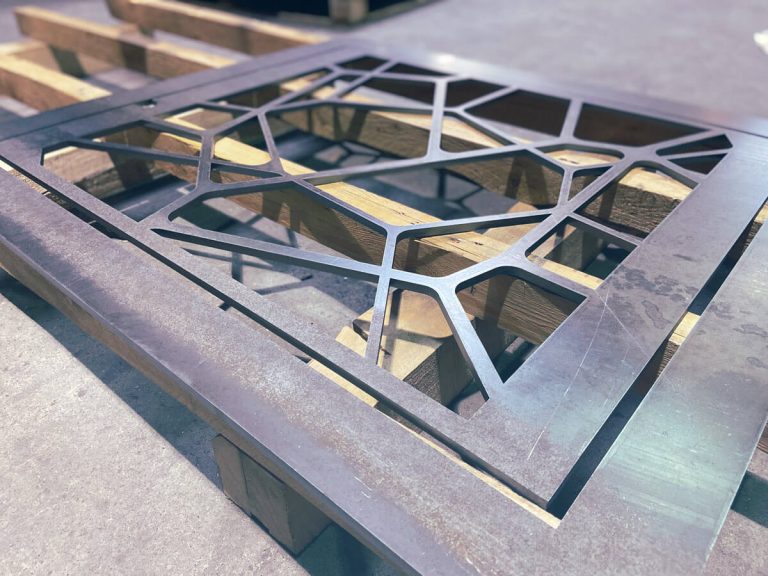

Metal processing through laser cutting of thick or thin sheets is a thermal separation process of the given element. This technique allows for extremely precise cutting of holes while leaving smooth edges along the cutting line. This type of metal processing is especially recommended for individuals who seek custom, intricate patterns. Laser cutting is based on a template embedded in the machine’s program – it can be freely modified and adjusted to meet specific needs.

Welding and Metalworking

ME Poland, thanks to its experienced team of engineers and skilled welders, provides comprehensive project execution, which includes the capabilities of its metalworking department. With this facility, the team is capable of manufacturing various steel structures, machine components, and architectural details, all requiring the highest quality, complex testing, and aesthetic finishing. Since 2018, ME Poland has obtained CE certifications for steel structural elements, including cold-formed ones.

If you require professional sheet metal processing, you don’t need to be located in Małopolska to take advantage of ME Poland’s services. The company invites all entrepreneurs and individuals who value high-quality workmanship and top-level services from across the country.