Machinery Park

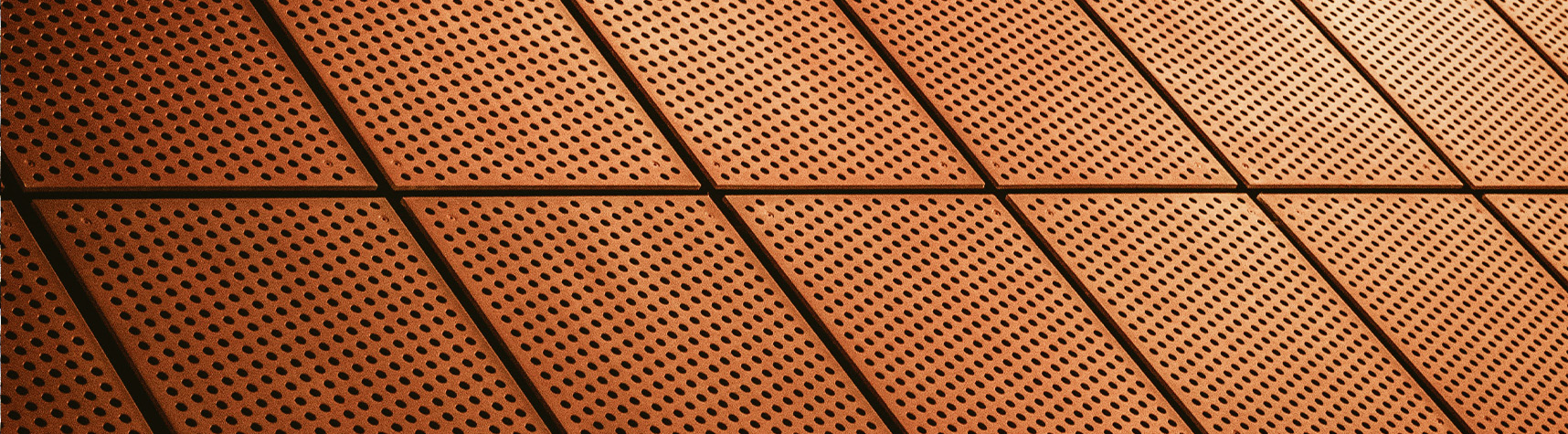

ME Poland, as one of the few companies in Poland, has a metalworking workshop that combines the capabilities of steel structure production and metalworking elements with modern facade solutions. These include perforated panels, facade louvers, acoustic louvers, facade panels with non-standard shapes, multi-folded sheet metal processing, and more.

TIG and MIG/MAG Welding Machines

ME Poland specializes in manufacturing complex steel and aluminum structures. With an experienced team of welders and certified quality control, the company holds a CE Certificate for the production of welded and cold-formed structures. They excel in producing elements with above-standard precision and aesthetics used in machine construction and furniture manufacturing. ME Poland performs welding on black steel, stainless steel, and aluminum.

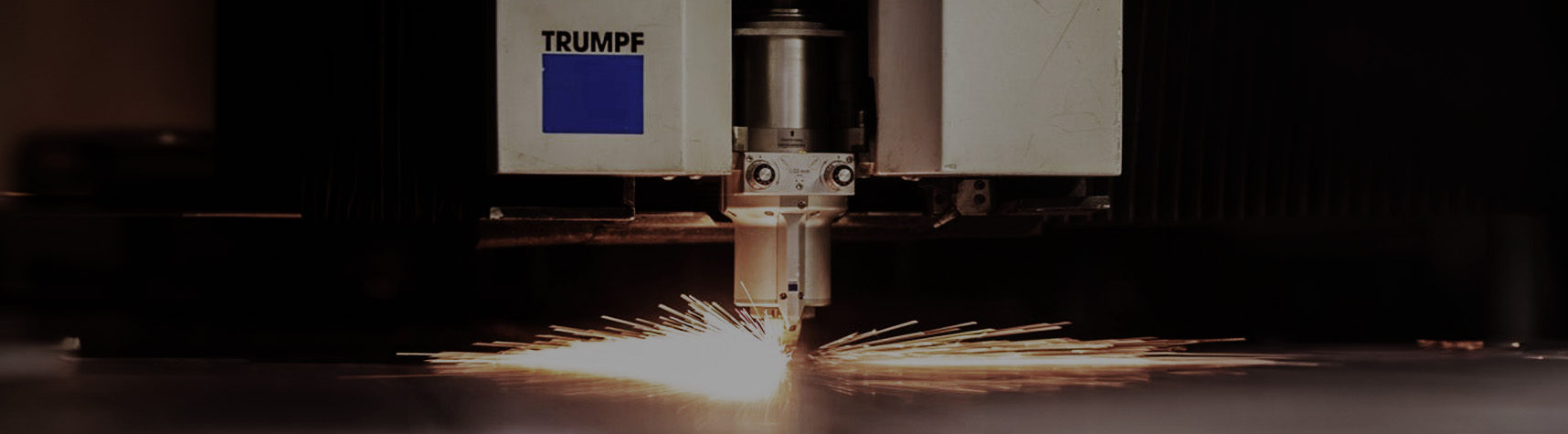

Laser

Max. Element Length:

6000 mmMax. Element Width:

2000 mmMax. Element Thickness:

16 mmME Poland utilizes lasers for cutting non-standard, intricate details with laser machines featuring a working area of 2000 mm x 6000 mm. Laser-cut elements can then be further processed through stamping, bending, or welding.

Bending Machine JORS Twin Matic

Pressure:

220 tMax. Element Length:

6400 mmMax. Element Thickness:

3 mmDuring the processing of galvanized and coated sheets through the shearing process on guillotines, the protective anti-corrosion layer will be drawn to the material's thickness, providing additional protection against degradation.

Shearing Guillotine LVD 6,2

Pressure:

220 tMax. Element Length:

3100 mmMax. Element Thickness:

5 mmDuring the processing of galvanized and coated sheets through the shearing process on guillotines, the protective anti-corrosion layer will be drawn to the material's thickness, providing additional protection against degradation.

Press Brake LVD 6,2

pressure

3200tMax length of the element

6200 mmMax. thickness of the element

20 mmThe ability to manufacture elements from thick and intricately shaped sheet metal. The press allows for the production of elements with non-parallel bends. The experience of operators, together with the machine, ensures accuracy and repeatability of the fabricated elements. The equipment is adapted to work with stainless steel sheets.

Revolver Punch Press LVD Strippit

Max. Element Length:

6000 mmMax. Element Width:

1250 mmMax. Element Thickness:

3 mmThe machine can create holes with various non-standard and complex shapes. It allows for the creation of customized patterns and designs. The appropriate tooling enables the execution of up to 9 holes in a single strike, at a rate of up to 5 strikes per second. During the processing of galvanized and coated sheets through the punching and blanking process on the turret punch press, the anti-corrosion protective layer is drawn to the material's thickness, providing additional protection against degradation. Perfect repeatability of fabricated elements. Possibility of station bending. Equipment adapted for processing stainless steel sheets.

Press Breake Vimercati 4.2

Max. Element Length:

4175 mmMax. Element Thickness:

5 mmPressure:

220 tFull automation of bending. Direct bending from 3D programs. Perfect repeatability of fabricated elements. Possibility of station bending. Equipment adapted for processing stainless steel sheets.